Not really a project update, but using the new modules to investigate a problem.

I now have both left and right bluetooth enabled Cat ECU's installed on the car. During the earlier part of the test phase, when I had built the first module and was testing it on the car, I had an occasional slow down light flicker. You can read about it and what I did with regard to sensitivity in one of the earlier updates.

Having got to the point where I had two bluetooth modules, and being able to show data on the phone screen in real time, I have carried out a lot more testing. One thing I have observed over this period is that after a time the left Cat ECU on my car begins to show a very noisy signal in comparison to the right one. This is representative of my original problem - after a period of driving the slow down light would come on and sometimes even the limp mode.

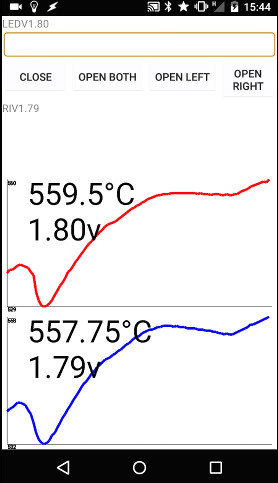

The first picture, here, shows everything running as it should be while I'm out on a drive.

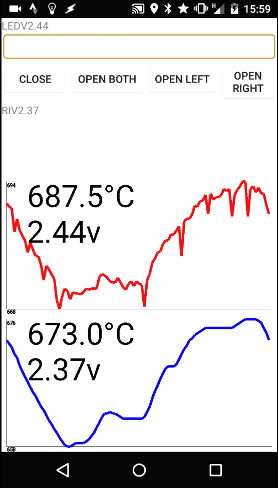

The second picture shows how the signal becomes noisy. You can see that the overall pattern is basically the same but the line is not smooth. I have observed that eventually the signal may be lost altogether which of course causes the warning light on the dash to go solid and for the left engine bank to be cut. At various times the level of noise changes and it doesn't seem to be dependent on engine revs or speed or going over bumps etc. What is most revealing about this is that without the modules I've built I'd have been completely in the dark about what is going on, so I wanted to talk a bit about the process I used to determine where the fault is.

The first thing to do with a 5.2 car is to work out which side the fault is on, because there is only one light on the dash covering both sides. This of course is very easy with the bluetooth charts; the red line is the left hand side. I know this because I wrote the software, but I guess I should really label them within the application.

The next thing to do is to try and work out which component is causing the problem. In an OEM system, you've got the following possibilities:

-

Broken power wires to the module

-

Broken signal wire from the module to the main ECU

-

Thermocouple connection

-

Thermocouple wires / nose

With an OEM module it is impossible to tell the difference between any of these if the warning light comes on. However, with the new module you can use a process of elimination to work out where the fault is. Note, in order to successfully investigate YOU MUST HAVE A MEANS TO RESET THE MIL LAMP VIA OBD-II (this also resets the slow down light):

Broken Power Wires to Module

If these wires are broken, the module will stop transmitting data. This is easy to see. The bluetooth link will die and need to be re-established. And if it can't be re-established then clearly the module has some sort of problem. By peering at the module you can see whether the power LEDs are lit, and if you know what to look for you can see whether the bluetooth module is ready and accepting connections (the LED flashes differently depending on whether a client is connected or not). In the worst case scenario you can plug in a USB cable to see if the rest of the module is alive using a laptop with a terminal application.

Broken signal wire

The best way to test this scenario is to use the terminal mode and set the unit to give a constant 500 celsius output. If this keeps the light off you know the ECU connection is good. The advantage of this mode is that it completely ignores the presence of the thermocouple. It is obviously not recommended to run in this mode permanently but it can be a good get you home mode if you have a thermocouple failure and are confident you do not have a cat overheat problem. You may need to reset the slow down light after enabling constant output mode to prevent engine bank cut, although on reflection this probably isn't necessary (but the light will keep flashing after the error has occurred).

I will add some settings to the phone app to control constant output mode in due course.

Thermocouple connection

If you have a good bluetooth connection then you can immediately see whether the thermocouple is connected. If it isn't the phone app shows -2 for the temperature (this is an error code in fact) and 5.0v for the output. For further veriffication it is possible to connect to the module using a terminal application over bluetooth and monitor the text based human readable error messages. This wil tell you how often a read failure occurs. You can also adjust the sensitivity up to 10 seconds if it is dropping out now and again; this is a good get you home workaround. The sensitivity basically says if there is a dropout and then the reading is restored, as long as the time between the two is less than the sensitivity limit then just ignore the dropout.

Testing for a bad thermocouple

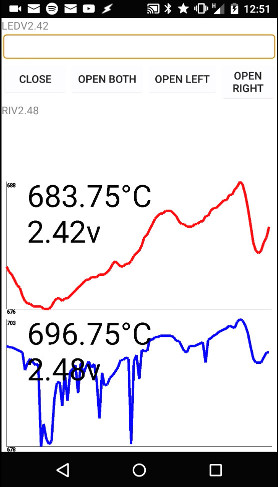

So you've got a noisy output like I have, and you want to work out whether it's the thermocouple or its connection, or whether maybe there is actually a problem with the electronics in the module. The easiest way to do this is not to swap the thermocouples over, but to swap the two modules. Put the left module on the right and vice-versa. When you do this, you have to remember what that means in terms of the phone application. It means that the red chart, whilst always showing data from the bluetooth module flagged as being the left module, is now showing data from the right hand side of the car. So if you have a thermocouple fault, despite not moving the thermocouple, it should appear as though the fault has moved sides.

You might want to think about that for a bit ;-)

This is where I was yesterday. I swapped the two units over and the fault switched from the left side to the right side. This confirms that the fault is the thermocouple and is not the module. It could still either be the connection or the thermocouple itself. The only way to verify this is to ensure all of the connections are made properly and then if there is still a fault, replace the thermocouple. I did find on my car that the male pins are fairly loose fitting inside the female connector from the thermocouple but having tightend them up I still seem to have a fault, so I think in my case the thermocouple itself has gone bad.

Here we are, with the two units swapped. Yes, you can swap the thermocouples first but these are harder to get to, require bigger spanners, and the worst bit is the thermocouples can be damaged on removal depending on how tight the were to insert in the first place. Especially if you have aftermarket cats.

So there you have it, a means to work out where the problem is instead of having to keep part swapping until the problem seems to have gone away!